Written by LaStarsha McGarity, Andrew W. Mellon Fellow in Objects Conservation at the

National Gallery of Art.

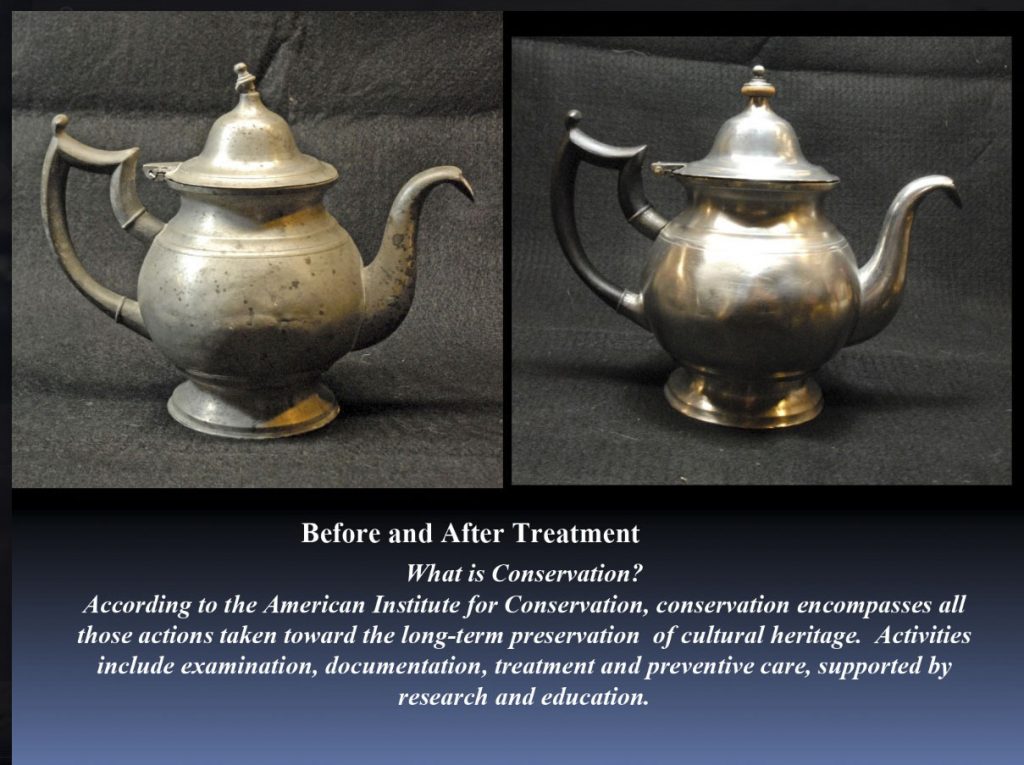

Presenter Edward McManus, retired Chief Conservator of the National Air and Space Museum, shared his passion for pewter technology and collecting at the 2020 Three Ring Circus by Washington Conservation Guild hosted in the S. Dillon Ripley Center. As a member of the Pewter Collectors’ Club of America, McManus wanted to challenge himself to treat a teapot that other collectors would have deemed worthless.

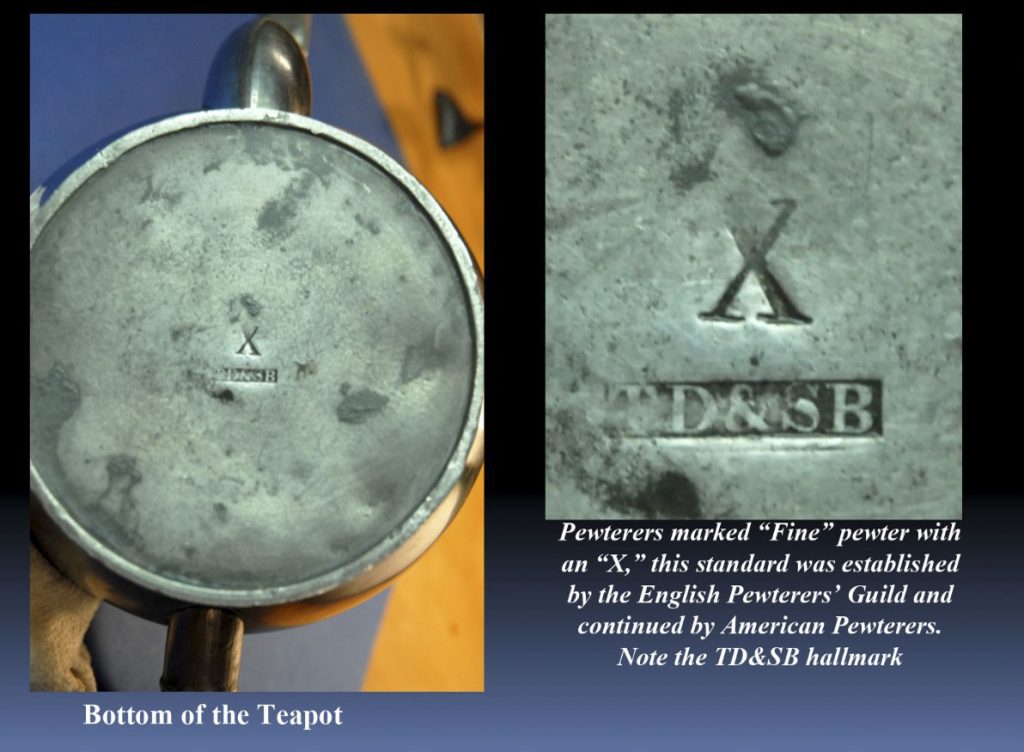

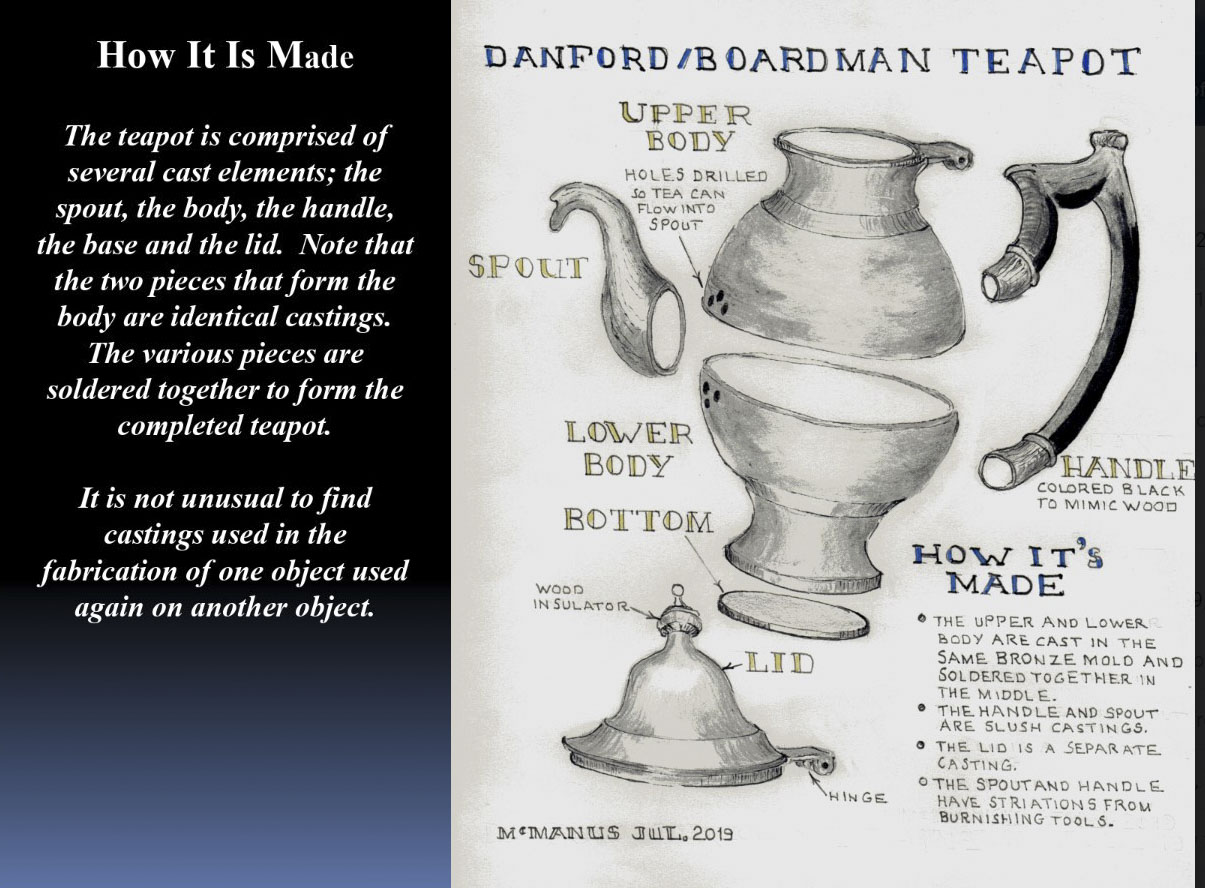

He purchased an antique pewter teapot, stamped on the bottom with a “X” for its fine alloy designation and “TD&SB” for the pewterers Thomas Danforth Boardman & Sherman Boardman (see image), from an antique gallery in Kilmarnock, VA. The teapot had a bent finial with a missing wooden element, a paperclip acting a hinge pin, and tin oxide corrosion on the surface.

X-ray fluorescence analysis was completed with a Tracer 5i pXRF by the Bruker vendor at the 2019 AIC Meeting in Uncasville, CT. The resulting percentages of 95.7% Sn, 1.74% Cu, and 1.8% Sb with traces of Ti, As, Zn, and Co are consistent with fine pewter alloys.

Treatment included mechanical straightening of the bent finial, fabrication and placement of a maple wood insulator, replacement of the paperclip with a pewter hinge pin, reduction of tin oxide surface corrosion with dilute HCl, and surface polishing with abrasives. Pits, the result of treatment with HCl (one of the standard treatment methodologies at this time), were filed to reduce their appearance prior to polishing. Dents in the body of the pot were removed with a jewelers’ planishing hammer.

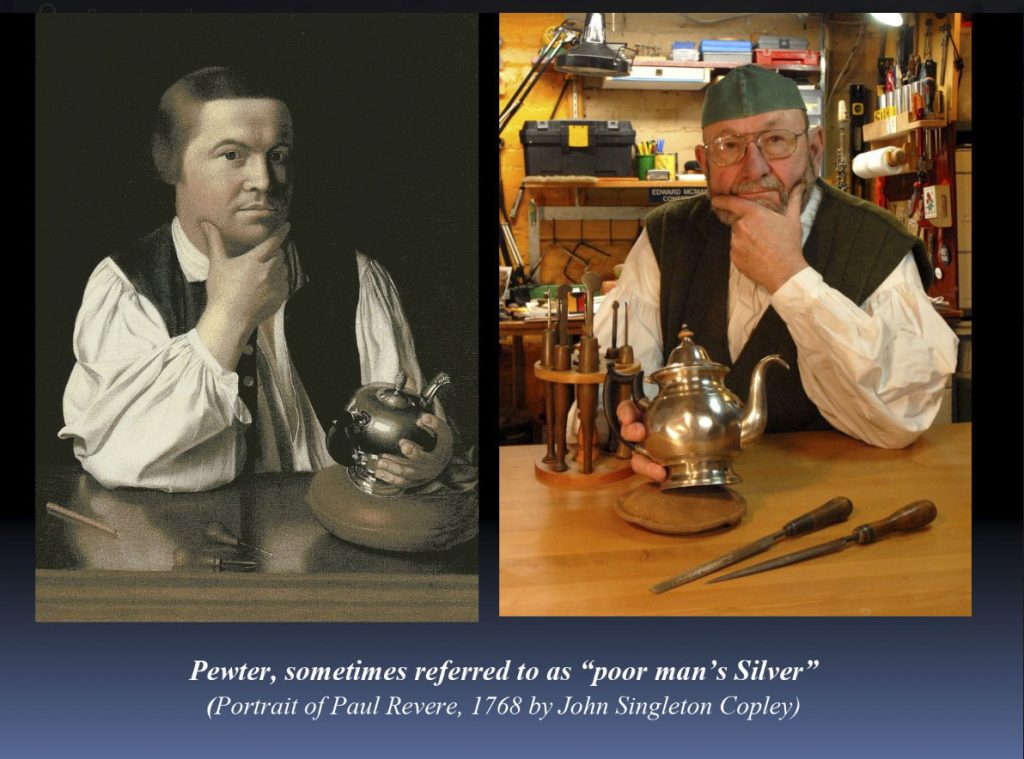

McManus hopes to bring more awareness of conservation to the ranks of pewter collectors and to open the dialogue between private collectors and conservators to further the ongoing preservation of the “poor man’s silver.”

I thoroughly enjoyed Edward’s passion for pewter, his explanation of how this pot was made, and his treatment process. As an avid tea-drinker and objects conservator I could not pass up the opportunity to learn more about objects related to tea.

Thank you to the coordinators of WCG for organizing this wonderful event that allows us the opportunity to learn from another.

Edward McManus recommends the following resources to those interested in collecting or understanding pewter:

The Bulletin produced by:

The Pewter Collectors’ Club of America, Inc.

https://www.pewtercollectorsclub.org/

https://www.pewtercollectorsclub.org/publications/sample-bulletin/

The Journal of the Pewter Society produced by:

The Pewter Society

https://www.pewtersociety.org/

https://www.pewtersociety.org/pewter-society/publications

Cited in the presentation:

Hudson, Moore N. Old Pewter, Brass, Copper, and Sheffield Plate. Frederick A. Stokes Company Publishers. New York, NY, 1905. (Reprintings are available)